How Durable Are Louver Fences?

Louver fences, which have recently been preferred by many people for their appearance and affordable prices, are, contrary to popular belief, very durable. Many people think that louver fences, especially due to the thickness of the louvers, cannot withstand strong winds. There are many louver fence models on the market, ranging from 0.6 mm to 1.2 mm in thickness. The most frequently asked question by those who want to purchase the product is about the louver thickness. The main reason for this is the perception that the louver thickness used is insufficient. Thicker louvers are thought to mean more durable fencing. However, this view is somewhat incomplete.

Louver thickness increases durability, but it is not the only factor. The factors determining the strength of the fence are:

- Louver thickness

- Louver design

- Number of louver bends and bend locations

- Louver sheet expansion

- Hardness of the louver material

- Post thickness and material

- Design of louver and post connection channels

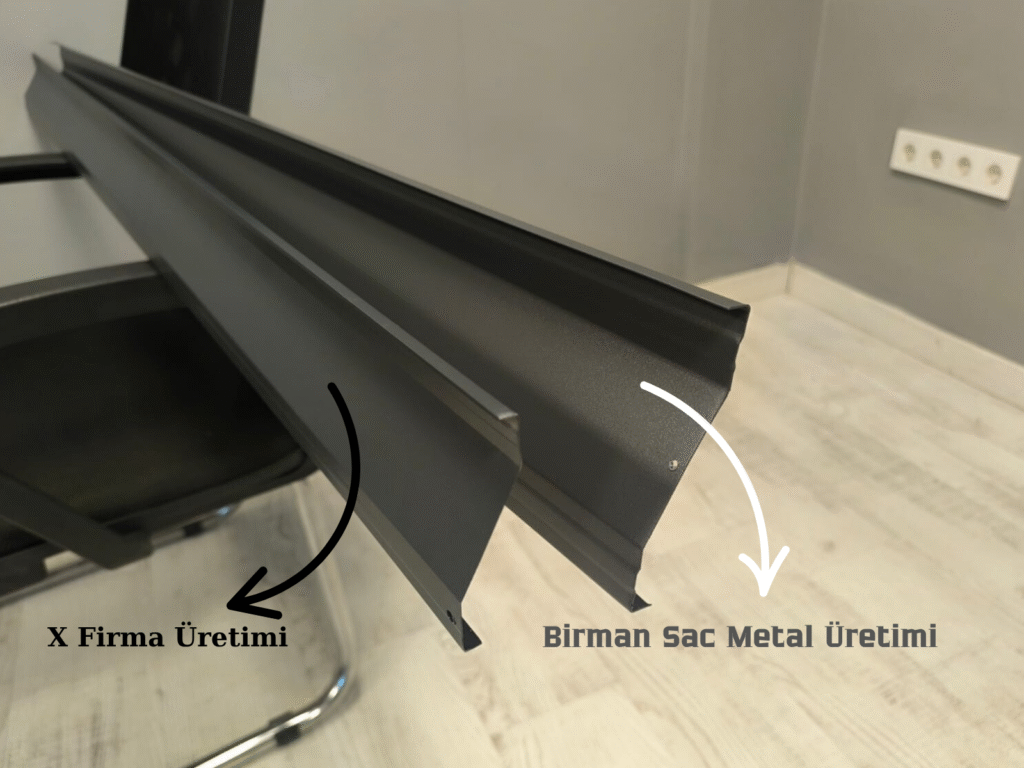

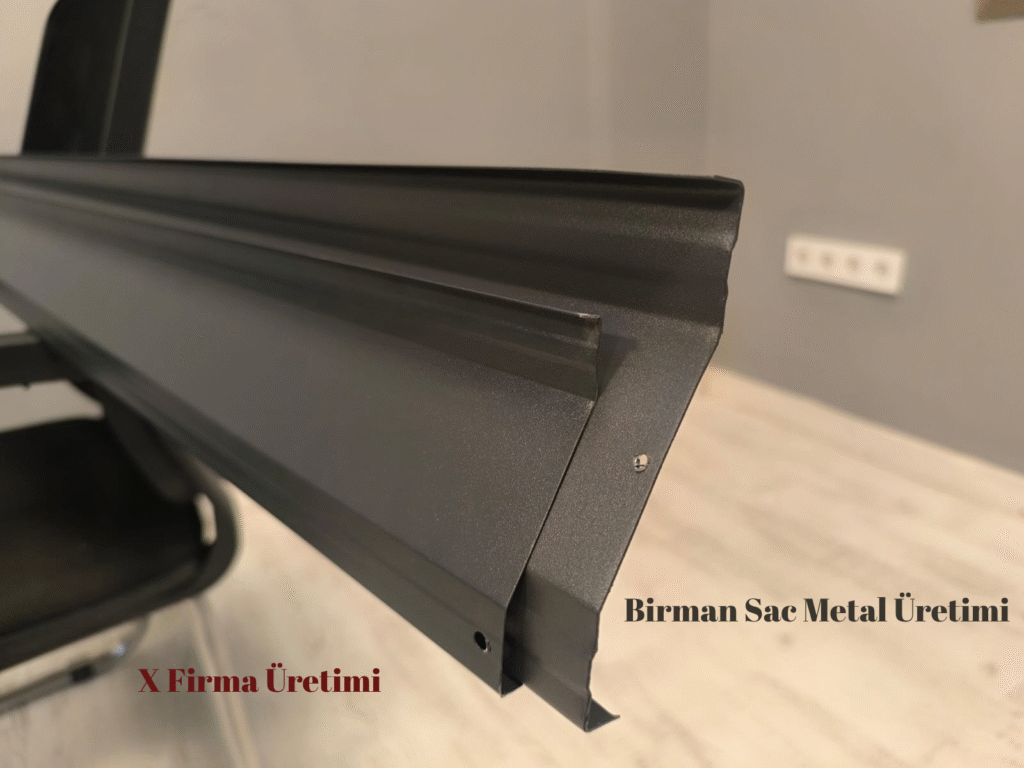

A louver fence made of 0.7 mm galvanized material can be many times stronger than a fence made of 1 mm material. Design, material used, and louver dimensions directly affect strength. A louver made of hard material with a thickness of 0.7 mm and a sheet expansion of 157 mm is much larger and stronger than a louver made of soft material with a thickness of 1 mm and a sheet expansion of 125 mm. Many manufacturers choose the softest material because it makes the work easier. Therefore, a thickness of 1 mm or 1.2 mm does not mean much.

Similarly, louver fences that cover the same vertical distance but have a narrow inner width, even if they are 1 mm thick, do not mean much. Louver fences with incorrect design and unsuitable materials will not provide the durability you desire.

Example of louver sold in 1mm and 1.2mm sizes on the market.

What Should Be the Desired Strength in Louver Fences?

Louver fences generally lose their integrity in a few ways.

- External impacts

Impacts from collisions or intentional blows can damage the louver. They cause bending and, very rarely, tearing. In these cases, usually a part of the fence or a certain number of louvers are damaged. Although these situations are undesirable for users, they are easy to remedy. Since louver fences are demountable, damaged louvers can be replaced with new ones.

- Paint degradation

This is a very common situation. Louver fences are usually painted with electrostatic powder coating. This painting technique is one of the best-known coating techniques. Powder coating is more of a coating process than a painting process. It is carried out by adhering paint pigments of a certain color to the metal material by creating an electromagnetic field, then holding it at 180-200 degrees Celsius for a certain time to liquefy and then harden. Cleanliness is very important in the powder coating process. Paints applied to unclean surfaces detach from the adhered surface in a short time. This is a major problem.

Another major problem in the powder coating process is cheap powder paints. The poor quality of their resins, in particular, causes the painted surfaces to fade quickly. Powder paints used other than well-known quality brands cause problems in outdoor areas.

One of the paint types used in the powder coating process is ‘underscreen’ paint. Underscreen paint refers to paints that have fallen or been collected from the air by suction systems during use, then sieved and reused. It is a very common method in the market. Manufacturers use this method because paint costs are high.

The use of underscreen paints is very dangerous. Dust and similar materials mixed into the paint significantly reduce the color and durability of the paint.

Reducing the baking temperature to shorten curing times also reduces paint quality.

- Wind effect

Wind is the biggest enemy of louver fences. Especially in settlements located by the sea, excessive winds can tear off all or part of the louver fences, or bend the louvers. Therefore, the design of the louvers and posts must be made by calculating the effect of wind in the louver fence design.

The maximum wind load that a structural element (1 meter wide, 10 cm high) can experience in Turkey is calculated according to TS EN 1991-1-4 (Eurocode 1) and the wind maps in the Turkish Building Earthquake Regulation. Here are the basic steps:

1. Basic Wind Speed (vb)

- In Turkey, the maximum basic wind speed is accepted as approximately 40 m/s (144 km/h) (e.g., windy regions like Bodrum, Antalya, Istanbul Strait).

- According to the maps, this value varies by region (e.g., 25-30 m/s in inland regions, 35-40 m/s in coastal areas).

2. Wind Load Calculation (Simplified)

Wind force (Fw) is calculated using the following formula:Fw=12⋅ρ⋅v2⋅Cd⋅AFw=21⋅ρ⋅v2⋅Cd⋅A

- ρ (air density): ~1.25 kg/m³

- v (wind speed): 40 m/s (maximum)

- Cd (drag coefficient): ~1.2 for a flat plate (varies by shape)

- A (surface area): 1 m × 0.1 m = 0.1 m²

Calculation:Fw=0.5⋅1.25⋅(40)2⋅1.2⋅0.1=120 N(≈12.2 kg-f)Fw=0.5⋅1.25⋅(40)2⋅1.2⋅0.1=120 N(≈12.2 kg-f)

3. Detailed Calculation According to TS EN 1991-1-4

- Height and Topography Factor: If the part is low to the ground (e.g., less than 10 m), c<sub>e</sub>(z) ≈ 1.0-2.0.

- Wind Pressure (qp):qp=0.613⋅vb2⋅ce(N/m2)qp=0.613⋅vb2⋅ce(N/m2)For 40 m/s:qp=0.613⋅1600⋅2=1961.6 N/m2(≈200 kg-f/m2)qp=0.613⋅1600⋅2=1961.6 N/m2(≈200 kg-f/m2)

- Net Force: Fw=qp⋅Cd⋅A=1961.6⋅1.2⋅0.1≈235.4 NFw=qp⋅Cd⋅A=1961.6⋅1.2⋅0.1≈235.4 N (≈ 24 kg-f).

4. Additional Factors

- Dynamic Wind Effect: Force can increase by 50% due to sudden wind gusts (turbulence).

- Structural Vibration: Risk of resonance in flexible parts.

Conclusion

- The maximum wind load that a 1 m × 10 cm part can experience in Turkey is approximately in the range of 200-350 N (20-35 kg-f).

- Static and dynamic analysis is recommended for critical structures.

The calculations above were made for a louver 1 meter wide and 10 cm high. Considering the harshest wind load in Turkey at 144 km/h, a louver of the given dimensions is exposed to an effect of approximately 200 to 350 N. This is an approximate pushing or pulling force of 30 kg. Even under these conditions, the louvers should not bend or detach.

By analyzing, we can see the reaction of a louver, made of 0.7 mm thick galvanized hard material, a product of Birman Sac Metal, when exposed to a 300 N impact from the front.

When we examine the analysis, the middle part of the louver deflects by 4.89 mm when subjected to a 300 N impact from the front. Since the louver is made of metal sheet material, this impact does not cause a permanent deformation in the louver material. This shows that a louver with this design will remain sturdy even against the strongest winds.

Similarly, we can analyze how the louver would react to an impact from above.

When we examine the analysis, a force of 450 N is applied to the louver from above. This is equivalent to a person weighing approximately 45 kg sitting on the louver. Under this impact, the louver deflects downwards by 2.17 mm. This impact also does not cause a permanent deformation in the louver.

Based on the results, a 0.7 mm thick product, when correctly designed and made with the right materials, demonstrates the required durability. In a product made with incorrect materials and design, louver thickness alone is not effective.

Factors such as material quality, design, and paint are important for purchasing a quality product.

Specifically, knowing the weight per square meter of the product can provide important clues about the product you are buying.